The MITSUSTAR cogged V-banded belts are especially well suited for critical drive systems in commercial vehicles and buses. Or where conventional, single or multiple belt drives are impractical because of space or weight limitations.

By means of their compact construction, vibrations of extended wheelbases can be considerably reduced. With their tear-resistant, transversely rigid top surface and precision-milled substructure, The MITSUSTAR cogged V-banded belts serve many vehicle manufacturers as a troubleshooter on high stress drives in air compressors, air conditioning units and ventilator fans.

The MITSUSTAR cogged V-banded belts are oil and heat resistant and antistatic, too. The Raw edge cogged banded cross sections are: RAX, RBX, 2RAVX10, 2RAX13, 2RXPB.

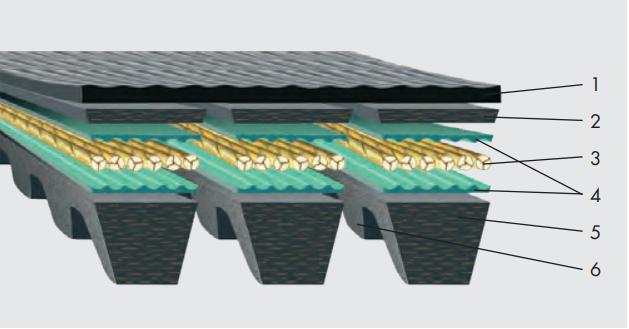

| 1. Tope Surface: The sheer Strength Polyamide fabric with CR rubber or EPDM rubber 2. Filler rubber: Durable polychloroprene-rubber compound and EPDM rubber compound. 3. Polyester tension cord. low maintenance 4. Cushion Layer: Adhesive polychloroprene-rubber compound and EPDM rubber compound 5. Belt body: Polychloroprene rubber compound or EPDM rubber with transverse oriented fiber 6. Moulded cogs: The sheer Strength Polyamide fabric with CR rubber or EPDM rubber |

Characteristics: 1. Low-maintenance Operation 2. Reliable running performance 4. High power transmission capability 5. Frame material: polyester string, cord |  |

| Profiles | ||||

| Section | Top width per Strand(mm) | Top width (mm) | Height(mm) | Strand (Rib) |

| RA(AJ) | 17 | 35 | 11 | 2 |

| RB(BJ) | 17 | 17 | 11 | 2 |

| RAVX10 | 10.5 | 10 | 2 | |

| RAVX13 | 13.6 | 12.3 | 2 | |

| RXPB | 16.3 | 16.5 | 2 | |

| RAVX13 | 13.6 | 44 | 12.3 | 3 |

| RXPB | 16.3 | 16.5 | 3 | |

| Application |

Most of banded V belts are primarily used for air solutions in commercial vehicle, construction and truck.    Product IntroductionBanded V Belt is a kind of belt which is widely used in various industries. It has two parts, the inner part and the outer part. The inner part is made of high quality rubber while the outer part is made of canvas or other materials. Banded V Belt is very strong and durable, and it can resist high temperatures and heavy loads. Product AdvantageBanded V Belt is an excellent product for those who are looking for a more durable and long lasting belt. The banding on the belt helps to keep it in place and prevents it from slipping. This makes it ideal for use in high torque applications. Additionally, the banded V belt can handle higher temperatures than other belts on the market, making it perfect for use in hot environments. Product UsesBanded V Belt Uses: Product Operate GuideBanded V belts are one of the most popular types of belts used in industrial applications. They are made up of several layers of fabric or rubber, with a metal or plastic band running along the inside edge. This type of belt is strong and durable, making it ideal for use in high-powered machinery. FAQBanded V Belt FAQ |

The MITSUSTAR cogged V-banded belts are especially well suited for critical drive systems in commercial vehicles and buses. Or where conventional, single or multiple belt drives are impractical because of space or weight limitations.

By means of their compact construction, vibrations of extended wheelbases can be considerably reduced. With their tear-resistant, transversely rigid top surface and precision-milled substructure, The MITSUSTAR cogged V-banded belts serve many vehicle manufacturers as a troubleshooter on high stress drives in air compressors, air conditioning units and ventilator fans.

The MITSUSTAR cogged V-banded belts are oil and heat resistant and antistatic, too. The Raw edge cogged banded cross sections are: RAX, RBX, 2RAVX10, 2RAX13, 2RXPB.

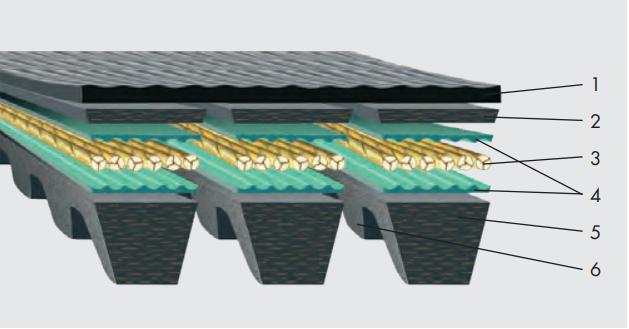

| 1. Tope Surface: The sheer Strength Polyamide fabric with CR rubber or EPDM rubber 2. Filler rubber: Durable polychloroprene-rubber compound and EPDM rubber compound. 3. Polyester tension cord. low maintenance 4. Cushion Layer: Adhesive polychloroprene-rubber compound and EPDM rubber compound 5. Belt body: Polychloroprene rubber compound or EPDM rubber with transverse oriented fiber 6. Moulded cogs: The sheer Strength Polyamide fabric with CR rubber or EPDM rubber |

Characteristics: 1. Low-maintenance Operation 2. Reliable running performance 4. High power transmission capability 5. Frame material: polyester string, cord |  |

| Profiles | ||||

| Section | Top width per Strand(mm) | Top width (mm) | Height(mm) | Strand (Rib) |

| RA(AJ) | 17 | 35 | 11 | 2 |

| RB(BJ) | 17 | 17 | 11 | 2 |

| RAVX10 | 10.5 | 10 | 2 | |

| RAVX13 | 13.6 | 12.3 | 2 | |

| RXPB | 16.3 | 16.5 | 2 | |

| RAVX13 | 13.6 | 44 | 12.3 | 3 |

| RXPB | 16.3 | 16.5 | 3 | |

| Application |

Most of banded V belts are primarily used for air solutions in commercial vehicle, construction and truck.    Product IntroductionBanded V Belt is a kind of belt which is widely used in various industries. It has two parts, the inner part and the outer part. The inner part is made of high quality rubber while the outer part is made of canvas or other materials. Banded V Belt is very strong and durable, and it can resist high temperatures and heavy loads. Product AdvantageBanded V Belt is an excellent product for those who are looking for a more durable and long lasting belt. The banding on the belt helps to keep it in place and prevents it from slipping. This makes it ideal for use in high torque applications. Additionally, the banded V belt can handle higher temperatures than other belts on the market, making it perfect for use in hot environments. Product UsesBanded V Belt Uses: Product Operate GuideBanded V belts are one of the most popular types of belts used in industrial applications. They are made up of several layers of fabric or rubber, with a metal or plastic band running along the inside edge. This type of belt is strong and durable, making it ideal for use in high-powered machinery. FAQBanded V Belt FAQ |